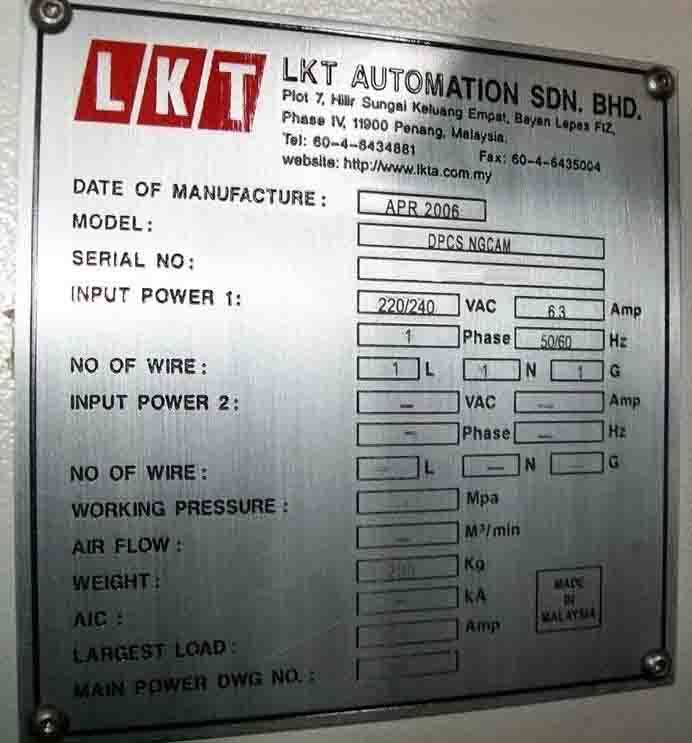

Used LKT AUTOMATION DPCS NGCAM #9070269 for sale

URL successfully copied!

Tap to zoom

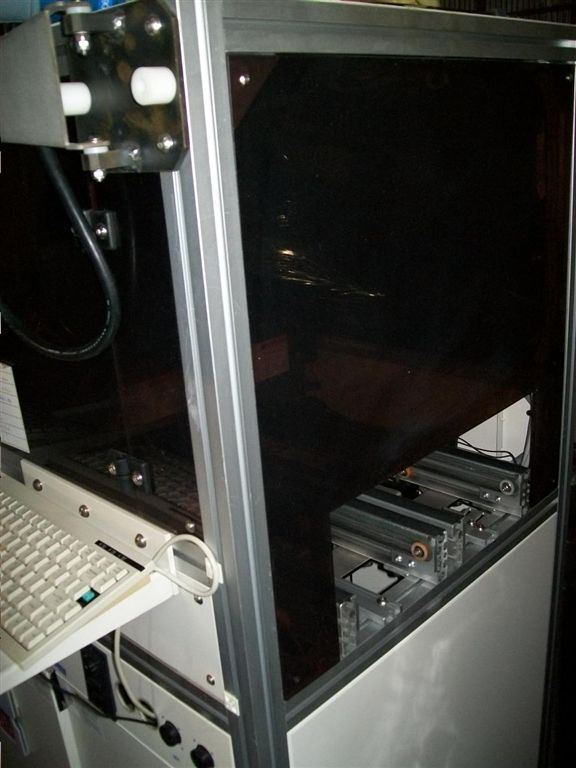

LKT AUTOMATION DPCS NGCAM is a high performance, fully-integrated PC Board Assembly and Manufacturing equipment designed to maximize productivity while delivering superior product quality. It provides automated component placement and soldering processes for the entire PC Board Assembly line, from the PCB itself through to component placement and soldering. The machine is equipped with a high-speed, dual-contact, dual-lane controlled surface mount pick-and-place technology that facilitates rapid component placement on any modern PC board. It offers a wide range of components from surface mount () to through hole (TH) components. The pick-and-place head is capable of placing over 400 components per minute in a safe and repeatable manner, perfect for assembly lines that need to meet tight deadlines. It also features an automatic vision inspection system that scans components for size and position before placement, ensuring complete accuracy. DPCS NGCAM also features a cutting-edge soldering unit which is highly efficient and accurate. It uses hot air and flux to solder components securely and accurately to the PC board. The flux is automatically applied to the pads, while the air pressure and temperature are adjusted to ensure a safe and reliable connection. The soldering parameters are easily adjustable and can be optimized for different components, ensuring superior product quality in the most demanding applications. LKT AUTOMATION DPCS NGCAM additionally offers a wide range of utilities and ease-of-use features to maximize productivity on the factory floor. Its user-friendly software allows for complete command and control of all the processes, including real-time monitoring of component placement and soldering. It also provides valuable traceability and auditability, along with next-step programming for more complex assembly processes. DPCS NGCAM is a powerful PC board assembly and manufacturing machine that offers a multitude of features and functions, all in order to increase efficiency and improve the quality of products. Its advanced pick-and-place and soldering technology ensures that components are always placed accurately, while its command and control software provide a safe and intuitive user interface. It is the perfect solution for any assembly line that needs to meet tight deadlines without sacrificing quality.

There are no reviews yet