DSX Protection Coating

Next Level Protection for Your Blades

DSX (Dragon Skin Xtreme) is a rotor blade leading edge erosion/corrosion protective coating. For 10- years DSX underwent rigorous testing and development before obtaining FAA approval in 2012. Since then DSX has developed a proven record in the harsh environments encountered by agricultural, fire, humanitarian, medical, and military operations. DSX has established its durability by over 3000 plus operating hours on a variety of rotor blades with no appreciable issues.

Stop wasting time and money with other so-called erosion coatings. Apply DSX to your rotor blades, it is the proven solution for erosion protection. DSX protects blades operating in sand, rain, saltwater atmospheres, and hydrolysis environments.

DSX Leading Edge Coating is FAA Approved

This patented, effective, high-quality coating can be used on, but not limited to, the following list of helicopter models:

- Bell 47 (Series)

- Bell 47 Wood Blade (Series)

- Bell 206 A & B (Series)

- Bell 206L (Series)

- Bell 407 (Series)

- Bell 412 (Series)

- Bell 505 (Series)

- Bell OH-58 (Series)

- Bell UH-1H, UH-1F, UH-1P, TH-1F and SW205 (Series)

- Airbus/Eurocopter BO 105 (Series)

- Airbus/Eurocopter 350 & 355(Series)

- Schweizer 269 (Series)

- Hiller UH-12(Series)

- MD Helicopter 369,500 (Series)

- Military AH-1, AH-64, CH-47, UH-60, MH-6

- Public Use Rotorcraft

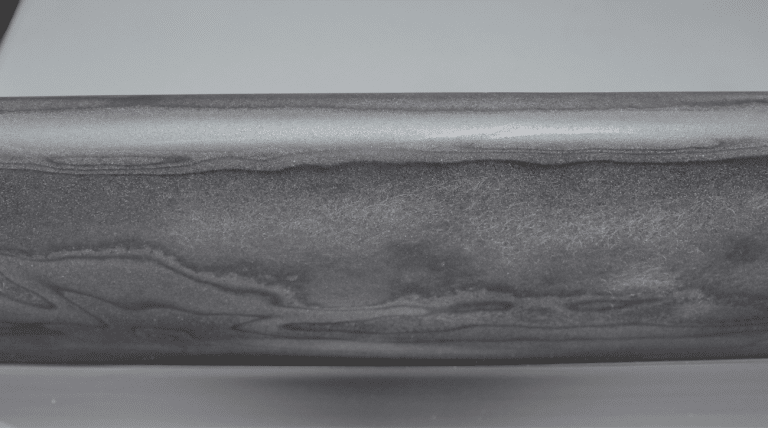

Old Blade Without Coating

Leading Edge of a Bell 206 B model main rotor blade that had been flown for 1000-hours in the agricultural industry. At this rate of erosion and corrosion this main rotor blade will NOT meet it’s life expectancy.

New Blade With Coating

Newly applied DSX leading edge coating to an OH-58 main rotor blade.

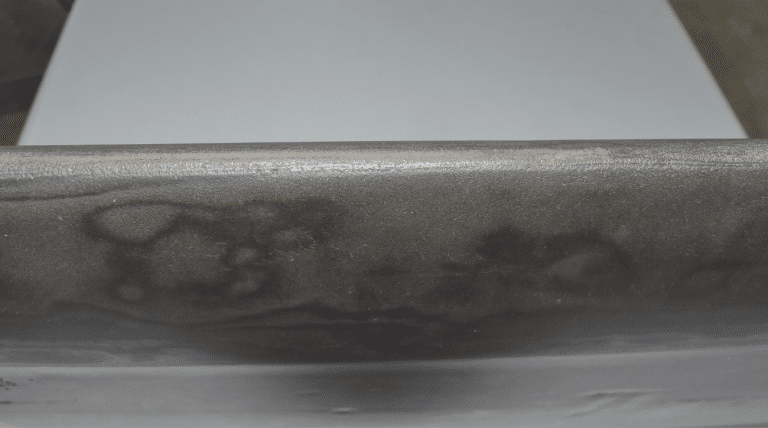

Old Blade With Coating

DSX leading edge coating applied to an OH-58 main rotor blade that had flown for more than 3000-hours in the agricultural industry.

Q&A

Where and how do I purchase DSX for my main rotor blades?

DSX is a product that is unique to Rotorcraft Repair & Manufacturing.

DSX may be purchased directly from Rotorcraft Repair & Manufacturing by calling us at (870)202-1454 or emailing us at info@rotorcraft.biz and scheduling your main rotor blades to come to our facility to have the DSX applied.

Is my helicopter eligible to have DSX applied to my rotor blades?

The following helicopter models are eligible to have DSX applied to their main rotor blades:

| Bell 47 | Bell UH-1H | Hiller UH-12 |

| Bell 206A & B | Bell UH-1F | MD Helicopter 369, 500 |

| Bell 206L, | Bell UH-1P | Schweizer 269, 300 |

| Bell OH-58 | Bell TH-1F | Boeing Apache AH-64 |

| Bell 407 | Bell SW205 | Boeing Chinook CH-47 |

| Bell 412 | Airbus/Eurocopter BO 105 | Sikorsky Blackhawk UH-60 |

| Bell AH-1 | Airbus/Eurocopter 350 & 355 | Airbus Gazelle 341 |

and many other types of military use rotorcraft, and public use rotorcraft.

Does my rotor blade qualify to have DSX applied to it?

We look for well-maintained or new main rotor blades with at least 40% of the life limit remaining to enter into the DSX program. Each situation and each rotor blade is different so give us a call and we can help you decide if DSX would be good for you.

What is necessary to prepare my rotor blade for DSX application?

There are no necessary steps you have to take, your main rotor blade will go through an extensive inspection process and if any repairs are needed, they will be completed before the application of DSX. DSX is generally applied to the rotor blade before it is refinished. Once the inspection process is carried out, and any repairs are made, then the DSX is applied, and the rotor blade is refinished.

Will this change how my helicopter operates?

No, this will not change how your helicopter operates, you will still follow all OEM requirements and recommendations. Although we have had testimony from clients that they do experience a smoother flight.

Is there instruction for continued airworthiness?

No, there are not any instructions for continued airworthiness, please follow the OEM requirements and recommendations.

Can I put DSX on one blade?

No, DSX must be applied to a set of main rotor blades, and they must be operated together. During the DSX process we go to great lengths to ensure the blades in the set match very well.

Will DSX change the weight & balance of my rotor blade?

No, the main rotor blades will be balanced to OEM standards.

Can I put DSX on my tail rotor blade?

No, DSX is not approved for tail rotor blade application. However, Rotorcraft Repair & Manufacturing is currently working toward approval for tail rotor blades.

What is the life expectancy of DSX?

We have seen DSX operated for more than 3000 hours without any issues or concerns.

How long will it take for my rotor blades to have DSX applied?

A small (MD 500) to medium (Bell 206) size blade will take on average of 3 weeks to complete and the large blades (UH-60) will take on average of 5 weeks to complete. This will vary depending on our current workload.

Is DSX FAA approved?

Yes, DSX was FAA approved in 2012, and has been successfully flying ever since.

Has DSX been tested?

Yes, DSX went through rigorous bench and flight testing over an 8-year period, during the process of FAA approval.

Does DSX change the life limit of the rotor blade?

No, DSX will not change the life limit of your main rotor blade, please follow OEM requirements and recommendations, however, DSX once applied generally lasts the lifetime of the rotor blade.

Will DSX have to be reapplied with every overhaul?

No, DSX may be inspected during the overhaul but will not have to be reapplied.

Can I repaint my blades without removing the DSX?

Yes, you can have your main rotor blades refinished without removing the DSX. It is recommended that you send your main rotor blades to Rotorcraft Repair & Manufacturing for refinishing.

Other than due to physical damage (blade strike) has DSX had a failure?

No, DSX has not had any type of failures during operation. The rotor blades in our DSX program come back for routine maintenance, inspection, and refinish, however, the DSX shows no damage.

Does the application of DSX cause my rotor blade to retain water in the spar?

No, the DSX will not cause water to be retained inside the blade. The blades that have drain holes in them, the drain holes will remain unobstructed.

Will my blade corrode under the DSX?

No, the main rotor blade will go through an intense preservation process before DSX is applied. The DSX application is an erosion prevention, that also stops the corrosion of the leading edge at the same time it eliminates the erosion of the leading edge.

Insight Customer Profiles

Discover how our premium coating services have significantly enhanced rotor blade performance and lifespan, as shared by those who have benefited from our DSX services.