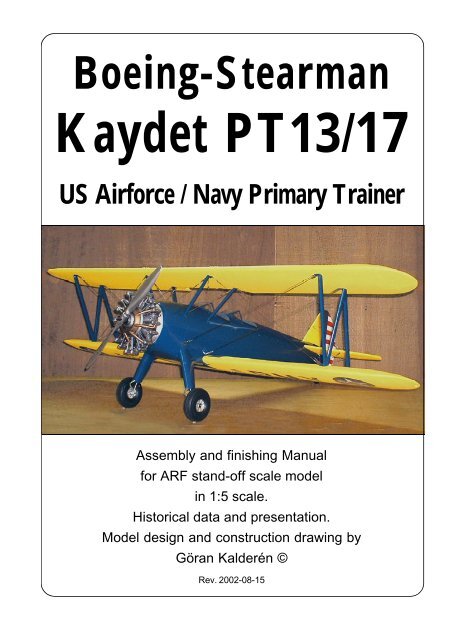

Boeing-Stearman Kaydet PT13/17 US Airforce / Navy Primary Trainer

Boeing-Stearman Kaydet PT13/17 US Airforce / Navy Primary Trainer

Boeing-Stearman Kaydet PT13/17 US Airforce / Navy Primary Trainer

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Boeing</strong>-<strong>Stearman</strong><br />

<strong>Kaydet</strong> <strong>PT13</strong>/<strong>17</strong><br />

<strong>US</strong> <strong>Airforce</strong> / <strong>Navy</strong> <strong>Primary</strong> <strong>Trainer</strong><br />

Assembly and finishing Manual<br />

for ARF stand-off scale model<br />

in 1:5 scale.<br />

Historical data and presentation.<br />

Model design and construction drawing by<br />

Göran Kalderén ©<br />

Rev. 2002-08-15

<strong>Stearman</strong> <strong>Kaydet</strong> PT<strong>17</strong> ARF 2

<strong>Stearman</strong> <strong>Kaydet</strong> PT<strong>17</strong> ARF 3

<strong>Stearman</strong> <strong>Kaydet</strong> PT<strong>17</strong> ARF 4

Boieng <strong>Stearman</strong> PT-<strong>17</strong> ’<strong>Kaydet</strong>’<br />

Nicknamed the ”Yellow Peril” thanks to its<br />

somewhat tricky ground handling characteristics, the<br />

<strong>Stearman</strong> is one of the most easily recognized aircraft.<br />

Its simple construction, rugged dependability and<br />

nimble handling made the <strong>Stearman</strong> much loved by<br />

those who flew and trained on it. The <strong>Stearman</strong> <strong>Kaydet</strong>,<br />

as it was officially named, was the only American aircraft<br />

used during World War II that was completely<br />

standardized for both Army and <strong>Navy</strong> use as the PT<br />

13D (Army) and N255 (<strong>Navy</strong>). Sold by the thousands<br />

after World War II, the <strong>Stearman</strong> has had a long and<br />

full career as a trainer, crop duster and air show performer.<br />

The famed <strong>Stearman</strong> Model 75 has its roots<br />

in the earlier Model 70, which was chosen in 1934 as<br />

the U.S. <strong>Navy</strong>’s primary trainer. At a time when biplanes<br />

were becoming a thing of the past, the Model<br />

70 offered the fledgling pilot a steady and sturdy steed.<br />

Designed and built in only 60 days, the prototype Model<br />

70 could withstand load factors much higher than were<br />

expected to occur in normal flight training. The U.S.<br />

Army and <strong>Navy</strong> tested the prototype in 1934. At the<br />

conclusion of these tests, the <strong>Navy</strong> ordered the aircraft<br />

while the Army decided to wait for the introduction<br />

of the improved Model 75 appearing in 1936. Over<br />

the next decade, the Armydecided to wait for the introduction<br />

of the improved Model 75 appearing in 1936.<br />

Over the next decade, the Army received nearly 8,500<br />

<strong>Stearman</strong>s in five different variants. The difference<br />

among these versions were the engines fitted; <strong>Kaydet</strong>s<br />

were fitted with Lycoming (PT 13), Continental (PT<br />

<strong>17</strong>) or Jacobs (PT 18) radial engines. The U.S. <strong>Navy</strong><br />

took delivery of their first <strong>Stearman</strong> (called the NS-1 )<br />

in 1934. Powered with the obsolete but readily available<br />

Wright R-790-8 engine, the NS-1 proved its worth<br />

as a primary trainer. The <strong>Navy</strong> purchased several thousand<br />

of an improved model, the N2S. The N2S was<br />

built in five sub variants, each variant being equipped<br />

with a different model engine. Additionally, the Canadian<br />

armed forces took delivery of 300 PT 27s, a winterized<br />

version of the PT <strong>17</strong>.<br />

A later, more powerful version of the <strong>Stearman</strong>,<br />

the Model 76, was purchased by Argentina, Brazil and<br />

the Philippines.<br />

<strong>Stearman</strong> <strong>Kaydet</strong> PT<strong>17</strong> ARF 5

<strong>Stearman</strong> PT-<strong>17</strong> <strong>Kaydet</strong><br />

Length: 25' 7.62 M<br />

Height: 9' 2" 2.79 M<br />

Wingspan: 32' 2" 9.80 M<br />

<strong>Stearman</strong> <strong>Kaydet</strong> PT<strong>17</strong> ARF 6<br />

Wingarea: 297.00 Sq Ft 27.59 Sq M<br />

Empty Weight: 1936.00 lbs 878.00 Kg<br />

Gross Weight: 27<strong>17</strong>.00 lbs 1232.00 Kg<br />

Powerplant: Continental R-670-5, 220 hp

The Model<br />

We have chosen the scale of 1:5 rendering<br />

a model size that i easy to fly but also relatively<br />

easy to transport. Both the upper and the lower<br />

wing panels can be removed for transportation<br />

which gives very limited requirement for<br />

transportation size. With a .1.20 4-stroke engine<br />

the airplane is capable of most of the manoeuvers<br />

in the book but still as docile as you can demand<br />

from a n advanced trainer.<br />

The finished model is painted in 1939 livery<br />

and further detailing can be made as per<br />

documentation.<br />

Specifications:<br />

Wingspan cm 193<br />

Wingspan inches 77.2<br />

Length cm 149<br />

Length inches 59.6<br />

Weight grams 6600<br />

Weight Lb/oz 14lb. 8 oz.<br />

Wing surface dm² 118 dm²<br />

Wing surface Sq.inch 1888 sq”<br />

Wing load g/dm² 56 g/dm²<br />

Wing load oz/Sq’ 24 oz/sq’<br />

Engine 2-cycle .60 - .90<br />

Engine 4-cycle .90 - 1.20<br />

C/G fr. Lead.edge upper wing 15cm / 6”<br />

Covering and finish<br />

The model is covered and painted from the<br />

factory. Where the original had aluminum covering<br />

panels, the model has the same. This also means<br />

excellent acces to the various compartments in<br />

the fuselage when installing or servicing the radio<br />

equipment. When you have made changes in the<br />

fire wall and adapted the dummy engine to fit in<br />

front of the engine, you will have to cover the open<br />

areas with fuel proof paint.<br />

Installation of engine.<br />

Our prototype was tried with an OS 1.20 FS<br />

surcharge 4-stroke which gave more than ample<br />

thrust. The engine mounts have been installed<br />

for this size of engine and in an upright position<br />

for several reasons.<br />

The need for adequate cooling. The access<br />

to the glow plug easily and finally to get the<br />

carburator in line with the center of the tank.<br />

1. Drill the holed for the engine in the ½"<br />

plywood ingine mount. Install blind nuts underside<br />

of the plywood aligned with the holes<br />

2. Drill the holes from the tank to the<br />

carburator, pressure tap and the filling cap.<br />

3. Install the engine and connect the throttle<br />

servo.<br />

No side or down thrust is deemed necessary. You<br />

can use an flexible exhaust manifold to lead the<br />

exhaust out under the center bottom panel to give<br />

a better apperance.<br />

Installation of servos, tank, battery and<br />

receiver.<br />

The aileron servo is installed in the cockpit<br />

flooring. The elevator servo and the rudder<br />

servo are also installed in the cockpit flooring.<br />

The trottle servo is installed behind the<br />

engine as well as the tank, booth on the<br />

engineboard.<br />

Battery pack and receiver are positioned<br />

in the upper part of the tray.<br />

The switch can be mounted on the front<br />

cockpit instrument panel.<br />

1. Attach a ball link head to joystick and<br />

rudder bar in the appropriate holes. You may have<br />

to enlarge the holes to take the screw from the<br />

ball link (Dubro #189 set of 2).<br />

2. Install the servos for rudder and elevator<br />

and temporarily connect the servo arms to the<br />

ball links. Deflection for elevator is 20° up and<br />

down and for rudder 30° right and left..<br />

3. Install and connect the throttle servo in<br />

the fashion you prefer.<br />

4. Install the tank in the available space at<br />

the right side next to the rudder and throttle<br />

servos..<br />

5. Install the aileron servo in the bulkhead.<br />

The aileron connecting rods attaches to the servo<br />

arm. Deflection of the ailerons should be 20° up<br />

and down. The servo arm should be fashioned to<br />

take 2 clevices approx 1/8" apart.<br />

6. Install the radio switch on the dash board.<br />

7. Place the receiver in the upper part of the<br />

tray and the battery pack in front of the lower<br />

firewall, wrapped in foam rubber and secured with<br />

rubber bands.<br />

Assembly of the PT<strong>17</strong><br />

All parts have been assembled at the factory<br />

and only disassembled for transportation.<br />

Rudder wires and elevator pushrod are<br />

factory adjusted but may need some tensioning<br />

adjustment after a while. Aileron bellcranks are<br />

permanently adjusted to the connecting rod.<br />

Assembly of the tail unit<br />

See detail drawing.<br />

1. Attach horizontal tail(3) to fuselage using 3 pcs<br />

4 mm nylon countersunk screws. Make sure that<br />

stabilizer is flat against fuselage.<br />

2. connect the elevator control rod to the elevator<br />

horn.<br />

3. Insert vertical fin and secure to tailpost bracket<br />

and front of stabilizer. Attach rudder on to the fin<br />

with hinge pins.<br />

4. Secure the assembly with screws to the<br />

stabilizer and to the tailpost. Attach the top<br />

stabilizer fairing and secure with screws.<br />

5. Attach fin and stabilixer support wires to top of<br />

fin using 2 mm screw and nut (from top side of<br />

<strong>Stearman</strong> <strong>Kaydet</strong> PT<strong>17</strong> ARF 7

<strong>Stearman</strong> <strong>Kaydet</strong> PT<strong>17</strong> ARF 8

<strong>Stearman</strong> <strong>Kaydet</strong> PT<strong>17</strong> ARF 9

stabilizer to top of fin).<br />

6. Secure and tighten all screws and nuts.<br />

Check the action of elevator and rudder. The<br />

elevator is actuated with the joy-stick and the<br />

rudder with the rudder bar.<br />

Assembly of wing panels<br />

1. Push the lower wing halves into the holes<br />

in the fuselage.<br />

2. Attach the upper wing center section using<br />

the 4 Allen 6-32 screws supplied (note that the<br />

front screws are longer and the rear screws<br />

shorter). Attach ball links or clevices to the aileron<br />

push rods. Connect the aileron push rods to the<br />

servo in the fuselage.. Check the movement of<br />

the ailerons. 20° up and 15° down throw.<br />

3. Install the interplane struts. Connect the<br />

flying wires and the landing wires. Attach the flying<br />

wires in place. Attach the landing wires in<br />

place. Adjust if necessary, the rear lower<br />

incidence adjustment screw and the fasten this<br />

assembly to the bracket on the lower wing using<br />

2 mm screw and locknut.<br />

Should you need to replace a wire, use the<br />

attachment method indicated in the picture. When<br />

crimping the cerulet (sleeve) use a flat plier, press<br />

firmly and don't cut through the wire.<br />

Landing gear<br />

Install the wheel shafts and secure with the<br />

Allen socket locking screws. The landing gear is<br />

completely built up with oleo spring action and is<br />

<strong>Stearman</strong> <strong>Kaydet</strong> PT<strong>17</strong> ARF 10<br />

an integrated part of the fuselage. The wheels<br />

are secured with locking rings and the wheel caps<br />

are pushed onto the wheel hubs.<br />

Balancing<br />

The center of gravity / balancing point should be<br />

approx. 15 cm (6") measured from the leading<br />

edge on the upper wing. Make adjustments if<br />

necessary.<br />

Flying<br />

The prototype was flown with a OS 1.20<br />

4-stroke FS which provides ample thrust. Let the<br />

engine swing a 18x6 propeller if possible. This<br />

gives better thrust outside the big dummy engine<br />

and reduces sound to a more realistic level.<br />

Flying characteristics are very forgiving<br />

and will fly hapily on half trottle. Set the elevator<br />

at zero angle for the first flight but be prepared<br />

to give down elevator if the model climbs out too<br />

steep. During the initial take off run you have to<br />

compensate for the torque with right rudder but<br />

as the speed builds up the rudder is returned to<br />

neutrual. This model should fly of the ground and<br />

not be pulled.<br />

The landing approach can be rather<br />

steep as per prototype but the flare out needs<br />

almost full up elevator. Maintain directional<br />

heading and remember, the aircraft has a<br />

stearable tailwheel.<br />

Happy landings!

The tailwheel is<br />

coupled to the<br />

rudder bar and has<br />

50% throw of the<br />

rudder<br />

Rudder and elevator servos in the flooring<br />

of front cockpit<br />

Aileron servo in the<br />

flooring of rear<br />

cockpit. Note the<br />

servo arm with 2<br />

attachment point<br />

for the clevices of<br />

the aileron push<br />

rods.<br />

The OS 1.2 engine blends nicely with the<br />

dummy engine<br />

Push rods from the servos attach to the<br />

rudder bar and the control column.<br />

<strong>Stearman</strong> <strong>Kaydet</strong> PT<strong>17</strong> ARF 11

What is in the box:<br />

The ARF kit contains the parts shown in the picture.<br />

All the parts are covered and painted. All the rigging<br />

5<br />

4<br />

3<br />

2<br />

1. Fuselage with wing cabane<br />

2. Landing gear<br />

3. Scale wheels<br />

4. Dummy engine with mount<br />

5. Scale propeller<br />

6. Tail wheel assy (stearable).<br />

7. Fin with tailfairing / rudder<br />

8. Stabilizer / elevator<br />

K&W<br />

11<br />

9<br />

<strong>Stearman</strong> <strong>Kaydet</strong> PT<strong>17</strong> ARF 12<br />

10<br />

Model<br />

Airplanes Inc.<br />

1<br />

wires are supplied in the correct lengths and need<br />

only to be clipped to their positions.<br />

9. Upper wing panels<br />

10. Lower wing panels<br />

11. Interplane struts<br />

12. Wires, turnbuckles and hardware for assembly<br />

(not shown)<br />

13. Assembly manual with scale<br />

documentation<br />

P.O.Box 1229, Cebu City Centrl. Postoffice<br />

Cebu City 6000, Philippines<br />

Visiting address:<br />

3343 Gun-Ob, Kinalumsan,<br />

Lapu-Lapu City 6015, PHILIPPINES<br />

Phone +63 32-340 0772, Cellular +63 9<strong>17</strong>-3200 985<br />

Telefax +63 32-340 7131, E-mail: kwmairpl@gsilink.com<br />

Website http://www.kwmairpl.com.ph<br />

8<br />

6<br />

13<br />

7